Sunday, December 20, 2009

Is going deep not going farther?

Wednesday, December 16, 2009

Just in time Discount for Just in Time Shoppers for Just in Time Books

Monday, December 07, 2009

Simple Inventory Control Example

- All his files are labeled and placed alphabetically. So, the file for "Kaizen Events" comes just ahead of the file for "Logistic Planning". He does not try to put subjects together, unless he names them as such (so, he told me, "Vendors-Critical" would be next to "Vendors-Potential")

- He creates new files as needed, such as when a new project comes up or a large file needs to be subdivided

- When he creates a new file, he removes an old file. He usually shreds or recycles the old file. Thus, he never takes up more space in the file drawers. And never needs to add space. Knowing him, I suspect his cube is neater than others as well.

Saturday, November 21, 2009

5S for Company Activities

If the horse is dead, dismount.

Sunday, November 01, 2009

Mixed Messages

Makes me wonder where I might be giving mixed messages. And, if I am, who will tell me? Is my organization robust enough to "see" the mixed messages and correct them?

Is yours?

Click here to subscribe to Learning about Lean by email.

Wednesday, October 21, 2009

You go to "gemba"--then what??

- Is the area neat? Is there any material here which should not be here? Is there something missing?

- Are the visual controls operating?

- Is the flow of material obvious, unobstructed, smooth?

- What is the mood? I can only tell if I speak with people, asking open ended questions and listening carefully.

- What are people saying about each other? Teamwork is always key; healthy relationships are a key barometer.

- Does anyone ask me a question? If not, they may feel they can't ask someone "above them". That's a problem. If they do, the nature of their questions tell me more of real concerns.

Wednesday, October 14, 2009

Kanban in a Resturaunt

A couple of weeks ago, we got a surprise while there. After our server brought us our food, she put a small red card on the table. "If you need a refill on your drinks, just flip this over," she said and walked away.

"This is a kanban card!" I exclaimed. My wife, a wonderfully patient woman, steeled herself once more for a monologue on pull systems and the beauty thereof.

Indeed, it was a pull system, in all its simple spendor but applied in a place not often expected to use such a tool.

The card is quite simple. If you are happy and don't need any attention, you leave the red side up, near the edge of your table. The server sees it and takes no action.

But once you are thirsty and need a refill (and those of you who have eaten with me realize this is often the case), you flip the card to green. Green means "go" and, in our experience, within 60 seconds a helpful server stops by, picks up the glass, confirms what drink you had, refills it, brings it back to the table and flips the card back to red.

It is just that simple.

Think about what this does for the customer. When you need service, you don't have to crane your neck, wondering if someone will stop by. Instead, you simply flip the card over and, soon, a person stops at the table. Conversation, the reason many eat out, continues uninterrupted. You finish sentences...you explore topics in depth... you don't wonder when or if you'll get another Diet Coke. In Lean terms, the customer gets more value.

Think as well what this does for McAlisters. The eye can move much faster than the foot. So, a simple scan by a server of a group of tables says, in seconds, who needs service and who wishes to be left alone. This allows a single server to handle more tables, more efficiently. Yeah, productivity.

All while providing added value to the customer.

At vitually no extra cost. All for a few laminated cards.

It is amazing what simple systems can do. Where can you apply this?

Click here to subscribe to Learning about Lean by email.

Sunday, September 20, 2009

How do we learn?

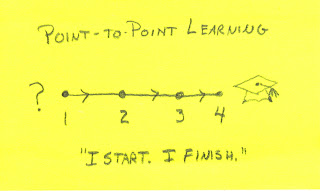

Most of us have a mental image of learning derived from our experience in school. We view learning as a linear process.

We start out needing to know something. We learn it. We progress through several intermediate points and then finish, knowing the subject. In this view, we are relentlessly "moving on," wanting to satisfy the current learning objective and then anxiously getting after the next topic.

An alternate view, however, is more accurate, he surmised, and I think is right as we learn and teach about Lean. In this perspective, learning is circular.

Rather than going from point to point, the learner comes round to the same things, but at progressively deeper, more complex levels. When viewed from the top, the learner appears to be only going round and round. A side view, however, reveals a corkscrew, not a circle. The learner comes back to topic again and again, digging progressively deeper and deeper into the topic.

In the 10+ years I've been pursuing Lean, I see this as a better mental model for learning. For example, I know about single-piece flow and have seen it work. But I still miss batches, all around me. I have much more to learn. I would be foolish to put a "check mark" next to "Flow" on my "Lean Curriculum" and seek to move onto the next subject.

For the one learning Lean, this means a conscious openness to learning more about things I already know. It means a posture of humility, recognizing I always have more to learn.

For the one leading Lean, this means an awareness that repetition is something to practice and not apologize for doing. It means being very aware of the next level of depth to which the individual learner must go. It means the leader must also be learning.

Depth comes from repetition. Don't be afraid of it.

And keep on learning.

Click here to subscribe to Learning about Lean by email.

Sunday, August 30, 2009

Four words to show "Respect for People"

- WHAT do you think?

- What DO you think?

- What do YOU think?

- What do you THINK?

Sunday, August 23, 2009

Perfection the enemy of improvement

Thursday, August 13, 2009

The Maddening Effectiveness of Root-Cause Analysis

Tuesday, July 28, 2009

MBWA, Micromangement and the difference between the two

Results results resultsThe stress of the current economic reality is driving our lean program into the ground. The boss is being beaten up daily by his bosses to show some kind of ROI on everything we do. So, instead of patiently watching as we are learning, we run around looking for any signs of measurement that can relieve the pain. Frankly, I would just as soon have him go back to management by teleconference

Available listens; micromanagement talks.Available encourages improvement; micromanagement demands instant results.Available shows up regularly; micromanagement appears only during crisis.Available shapes; micromanagement pounds.

Sunday, July 26, 2009

When do email discussions lose value?

Thursday, July 16, 2009

Management by NOT Wandering Around

Sunday, July 12, 2009

A Question to Discern Strengths

"What do you love to do and do well?"

Saturday, July 04, 2009

Why is everything all lined up?

Sunday, May 03, 2009

Structural Waste

Wednesday, April 29, 2009

Value-Added Data Entry

Sunday, April 26, 2009

So what DOES an engineer do?

Monday, April 13, 2009

Trimming Value at the Margins

Friday, April 10, 2009

What price sophistication?

Saturday, April 04, 2009

The Chain

Sunday, March 22, 2009

The psycology of going to gemba

Tuesday, March 10, 2009

Making a go from batch to flow

Tuesday, March 03, 2009

On being nimble vs visionary

"We stand resolved that the ability to react is now more important than the ability to predict."

As I read this, it hit me as very applicable to any setting in which we seek to deliver value to a customer. Customers change their mind. The worlds in which our customers work change, constantly, in ways we can never predict. Clearly, the current economic downturn is creating more uncertainty than we have seen in a generation.

So why would we attempt to "predict" the future? Why not focus instead on being able to react more rapidly than ever? To be more nimble, more versatile, more flexible? To build systems and people to be responsive? To build systems which do not depend on being clairvoyant?

The answer is obvious. And is the Lean leader should be spending time.

Keep on learning.

Sunday, February 08, 2009

Two Golden Geese

And in this case, it is not one goose but two.

The first goose is the daily start up meeting.

Taking only six to eight minutes, a work-group leader gathers all of her team members at the start of the shift. She then does a very short and prescribed thing each day. Standing next to a visual display of work group information, she greets the team, sincerely. She briefly discusses the previous day's work, how the actual results compared to the planned results. She then describes this day's plans. She asks the team about any schedule issues which might affect their work that day. She answers any questions or makes a point to answer them later. She then wishes everyone well at the start of the day.

Every day.

Why does this work? It sets the tone. It answers the most basic of questions about the work day. It resets the minds and expectations of the team members from the chaotic world outside of work. It is a point of daily contact.

It's an egg of gold, at the start of each shift in each work group.

The second gold-producing goose is the simple workplace walk through.

I've done this for years and it simply never fails to improve something; either a question answered, an insight I gain, an improvement to be made. And it costs nothing but time.

The walk through is exactly that. A leader getting to the place the work happens. Literally. To a place he can touch the work and, literally, have his elbow touch the elbow of the person doing the work. If elbows don't touch, it isn't close enough. When that close, the leader must see, hear and sense the reality of the work place. And, once doing that, things improve. Always.

What is really amazing here? Both geese are free. Public Domain, baby. No intellectual property rights violated. Both can start now. No seminar to go to. No consultants to pay. You decide...and the goose is yours. From that point, you just feed and care for the critter. And daily get a gold egg.

I'm talking to myself. And to you.

Go enjoy the gold.

Click here to subscribe to Learning about Lean by email.

Thursday, February 05, 2009

Make mine sausage with extra cheese

While training some new associates on the use of kanban cards, she discovered some misunderstandings. Some felt that they needed to take the card, walk over to the supply crib, get the supplies and walk back to their workplace. They didn't grasp the use of the kanban post and the role of the water spider to come by at prescribed times, take the cards and replenish the supplies.

"Think of it this way," April started in. "You're at home and want some pizza. You have two options, right? You can get in your car, go to the pizza place and bring it home. Or you can call the pizza place and have it delivered."

Everyone nodded, their mouths salivating slightly for some tomato paste on thin crust.

"Well, the kanban card is like the pizza delivery guy. You place the card in the post and that's the 'order' to be delivered later."

Lights came on. The kanban card is the order. That's all I need to do.

April then used the opportunity to show waste: "Further, you don't want to make all those trips to the pizza joint. That's just wasting time and gas." Everyone nodded.

"And, you know the best part of our 'delivery' via kanban?" She had some puzzled looks and she knew she had the audience. "You don't have to tip the driver!"

She made the point, and made it memorable, with a clear, simple example from everyday life.

Feel free to use it!! And don't forget the bread sticks!

Click here to subscribe to Learning about Lean by email.

Thursday, January 29, 2009

Discerning Leadership Potential

Tuesday, January 27, 2009

Generating Waste via email--an example

Sunday, January 11, 2009

Doing Lean: Remember the Basics

Monday, January 5 was a startling wake up. Like a race car coming out of a series of slow, easy turns onto a long straightaway, the sudden acceleration was alarming this week. It’s easy for me to lose my perspective in this sudden change; I suspect I’m not alone.

So, I’m reminding myself to pay attention to Lean basics this week, just to keep myself in the habit.

Make it flow I’m looking for anything that gets in the way of a product moving smoothly from start to finish, with no interruption. Evidence includes piles of stuff, people waiting, people in panic, wanting to “expedite”.

Cut the batch size A seldom-talked-about tool in Lean is to simply cut any batch size in half or thirds. Almost without question, just cut the bath size closer and closer to a single unit. But not just in a production setting. Have a monthly review meeting? Make it bi-monthly or weekly. Have a weekly status update? Do it on Monday and Thursday. It’s amazing to me but almost without exception, cutting the batch size improves customer service and speeds flow. I’ve got some work to do here.

Make the plan; measure the actual Assessing plan to actual shows many forms of waste and is so very, very easy to do. When actual is either better or worse than plan, I need to ask “Why” five times. This drives understanding and is a huge, almost free, source of improvement targets. But it assumes a) I have a plan and b) I can measure it. Both are easy. Both require a habit.

Local Improvements These three should unleash for us (and for you) a steady stream of improvements. Remember, world-class companies have 2 improvements per employee per month. Yes, per month. Find it, write it up, make it stick.

Here’s hoping for a very productive 2009 for all of us.

Click here to subscribe to Learning about Lean by email.